Products

- Wrapped Cover Wire Spiral Hydraulic Hose (27)

- wrapped & smooth braided hyraulic hose (43)

- Acid Frac Hose (4)

- Oilfield Drilling Hose (35)

- Floating Hose (123)

- Industrial Hose (49)

- Fiber Braided Hose (30)

- Hydraulic Fitting (224)

- Hose Assembly (2)

- Liquid Cooling Hose (3)

- Concrete Pumping Hose (2)

- Ultra High Pressure Thermoplastic Hose (8)

- Hydraulic Adapter (283)

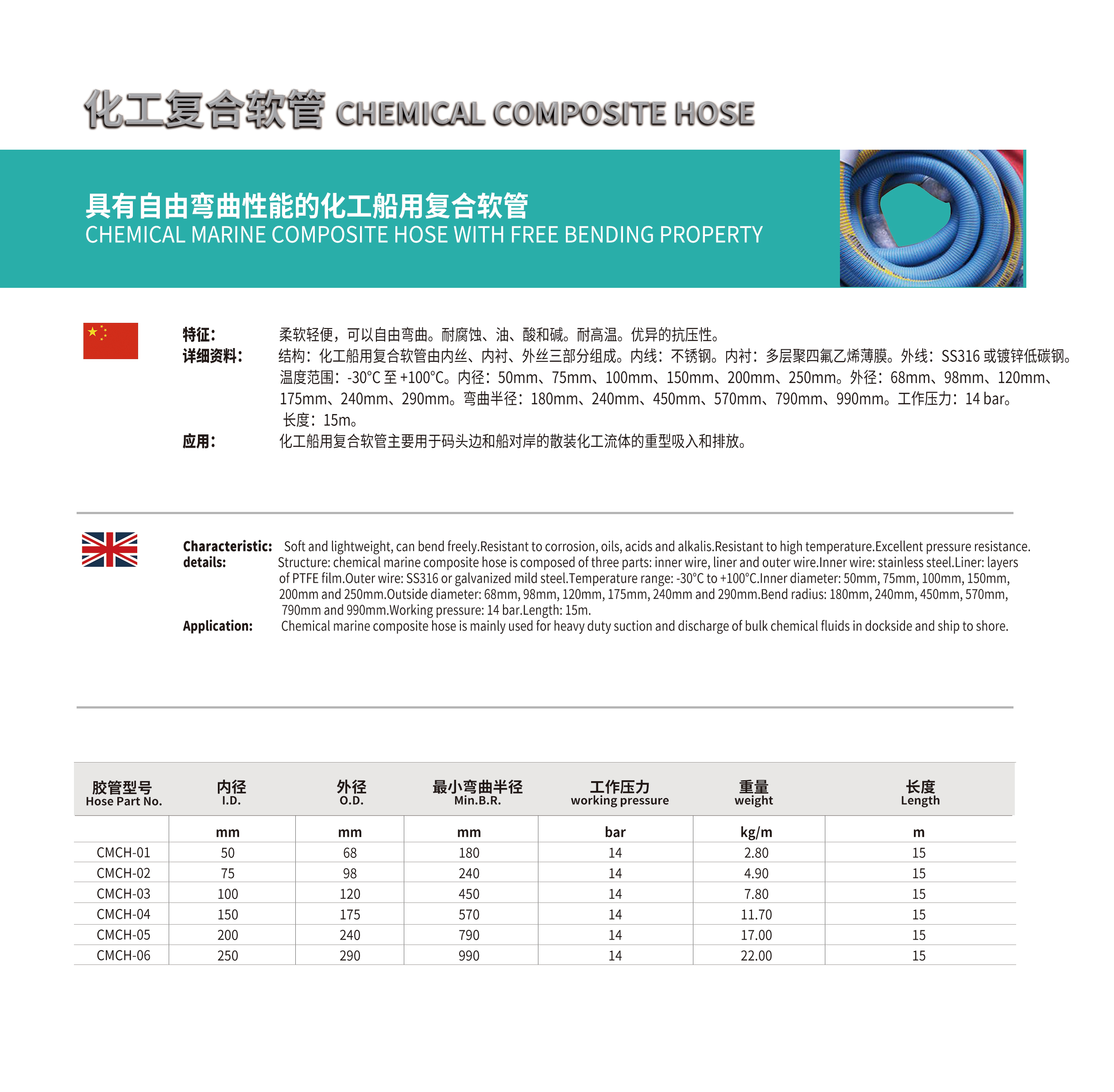

CHEMICAL COMPOSITE HOSE

CHEMICAL MARINE COMPOSITE HOSE WITH FREE BENDING PROPERTY

-

Chemical marine composite hose is mainly used for heavy duty suction and discharge of bulk chemicals in dockside and ship to shore. It is soft and lightweight. And it can bend freely, making it easier to operate. It is resistant to oils, acids, alkalis, high pressure, high temperature and corrosion. It is composed of three parts: inner wire, liner and outside wire.

Product Details