Products

- Wrapped Cover Wire Spiral Hydraulic Hose (27)

- wrapped & smooth braided hyraulic hose (43)

- Acid Frac Hose (4)

- Oilfield Drilling Hose (35)

- Floating Hose (123)

- Industrial Hose (49)

- Fiber Braided Hose (30)

- Hydraulic Fitting (224)

- Hose Assembly (2)

- Liquid Cooling Hose (3)

- Concrete Pumping Hose (2)

- Ultra High Pressure Thermoplastic Hose (8)

- Hydraulic Adapter (283)

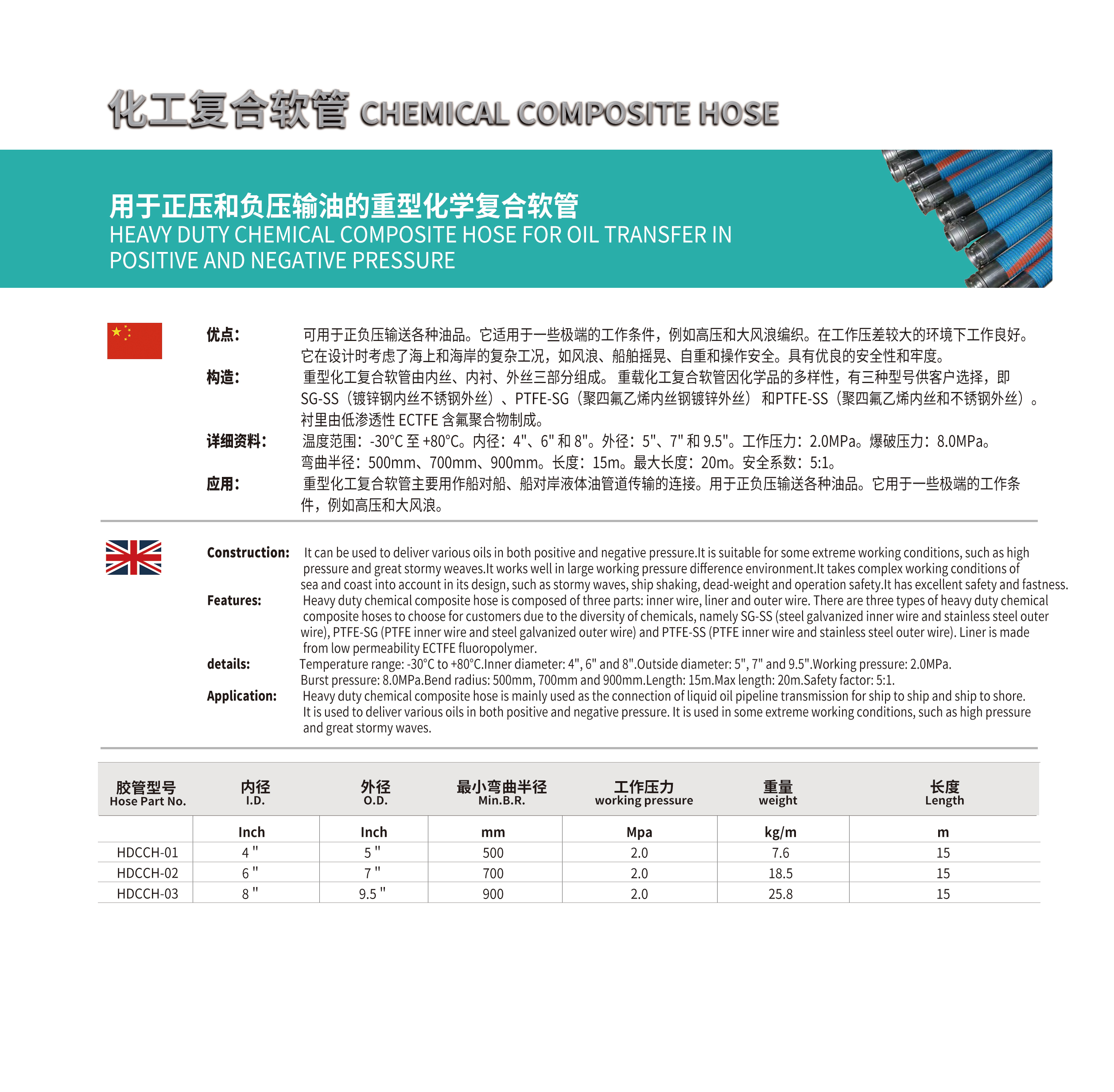

CHEMICAL COMPOSITE HOSE

HEAVY DUTY CHEMICAL COMPOSITE HOSE FOR OIL TRANSFER IN POSITIVE AND NEGATIVE PRESSURE

Heavy duty chemical composite hose is suitable for some extreme working conditions, such as high pressure and great stormy waves. It can be used to deliver various oils in positive and negative pressure. It is often used as the connection of liquid oil pipeline transmission for ship to ship and ship to shore. It is very soft and it can bend freely, making it easier to operate for workers.

Product Details